Metal products manufactured in accordance with quality standards EN 3834 and EN 1090:

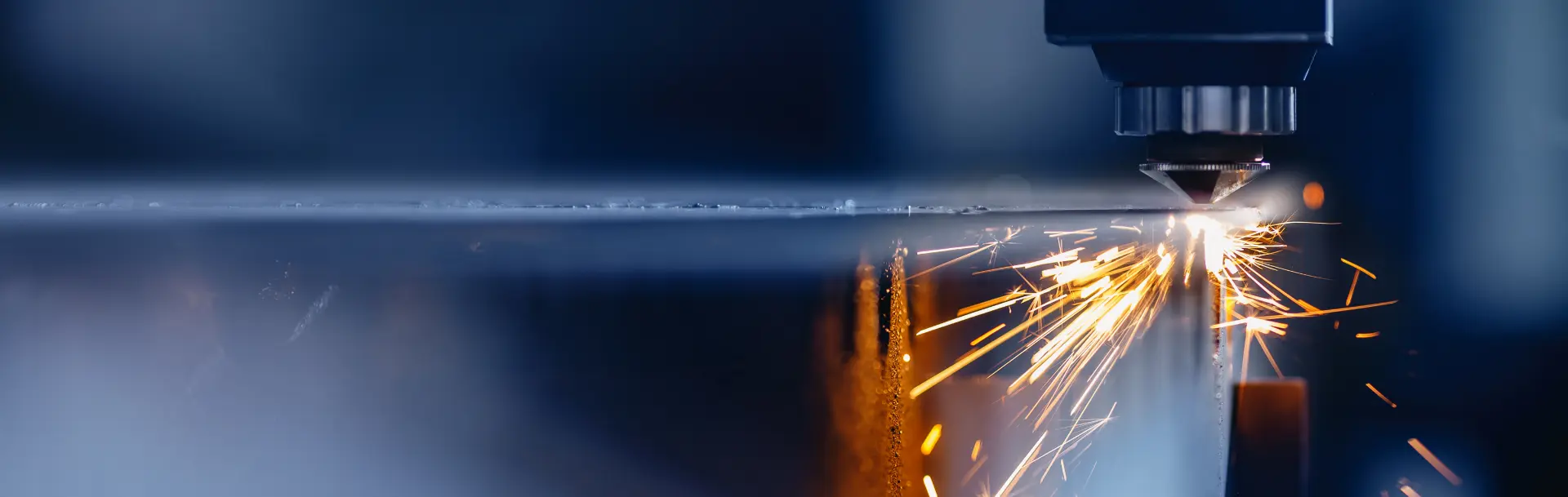

- Plasma and oxyfuel cutting

- Cutting and drilling for structural steel profiles

- Welding of subassemblies

- Airless blasting and painting against corrosion

- Non-destructive testing with ultrasonic liquid penetrant

- Chemical analysis using spectral method

State-of-the-art production equipment for quality and performance:

- CNC line - FICEP for processing steel profiles such as IPE, HEA, HEB, UNP

- Drilling unit and a band cutting unit

- PEGAS band cutting lines for cutting steel profiles and pipes

- CNC plasma or oxyacetylene cutting machines by ESAB for steel plates, ranging from simple to complex shapes, with sheet thicknesses between 3 and 180 mm

- SUPRABLAST automatic blasting installation

- Gas shielded wire welding equipment - MIG - MAG (Jackle, EWM, Kemppi, ESAB)

- Combined GEKA shear, RIDGID bolt threading machines

- Radial drilling machine

- Airless painting equipment

- GTV Blast paint booth

We honor our clients' orders by paying maximum attention to every detail in the execution processes.